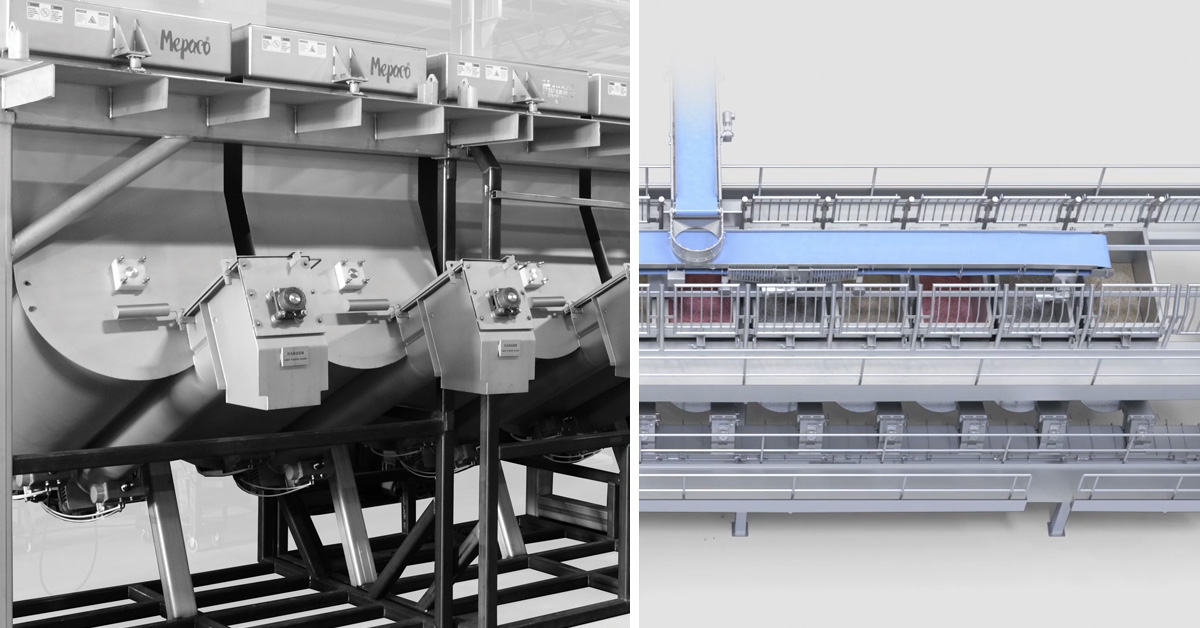

The Metering Screw Conveyor with surge loading capabilities is the key equipment component in this (above) 24/7 formulation line.

In the system above, pre-broken frozen food products (red meat, fish, chicken, vegetables) are delivered to a designated metering screw on a traversing belt which locates the exact drop position. Once the recipe is established and the demand is made, the applicable metering screws deliver product.

Load cells are used to measure product displacement over a given time (loss-in-weight method). Mixers, blenders, or cookers signal for the raw materials in a given SKU, and the surge loading metering screw conveyors will deliver the correct quantity of product required through the primary grinder and then to the batch for final formulation.

Metering screws have versatile designs that are suitable for different food handling requirements:

- Applications for the cross-screw hopper include trim meat and course or fine ground meats (fresh or frozen).

- The best-fit applications for clean sweep hopper designs are course or ground meats or food product (fresh or frozen).

- The dual-screw design is often considered in trim and / or whole muscle applications.

Metering Screws provide the surge loading benefits required to fulfill production goals in the batch formulation system above. The clean-sweep Metering Screw has an off-set screw agitator designed to clear food product from the hopper between batches. This batch processing line reduced labor and eliminated downtime with continuous, 24/7 large batch production: utilizing real-time material availability and on-demand formulation.