With the

With the

complex demands in food processing and production, safety, and quality, every component within food equipment is critical. Any machinery with moving parts will utilize bearings.

Here are some tips to reduce wear issues and extend bearing life:

- Mount the bearing correctly after maintenance. Make sure shims are re-installed and that the shaft is correctly positioned, and make sure that the shaft and bearing housing have the correct tolerance. A bearing sitting loose on a shaft will cause significant damage to the shaft.

- Grease bearings according to manufacturer recommendations. A low RPM bearing on a mixer will not require grease as often than a grinder gearbox bearing. One grease schedule does not fit all bearings.

- Use the correct food-grade lubrication in the right quantity. Over-lubrication can blow out the grease seal, under lubricating can increase friction and cause failure.

Seals protect bearing lubrication by keeping moisture, dust, and dirt out of the bearing; make sure seals are inspected and maintained properly. - Check bearings regularly for excessive play and replace bad bearings before they cause damage to the equipment. Replacing a bearing is much less expensive than replacing a worn and grooved shaft.

- Choose the bearing type that will uphold to the food processing application.

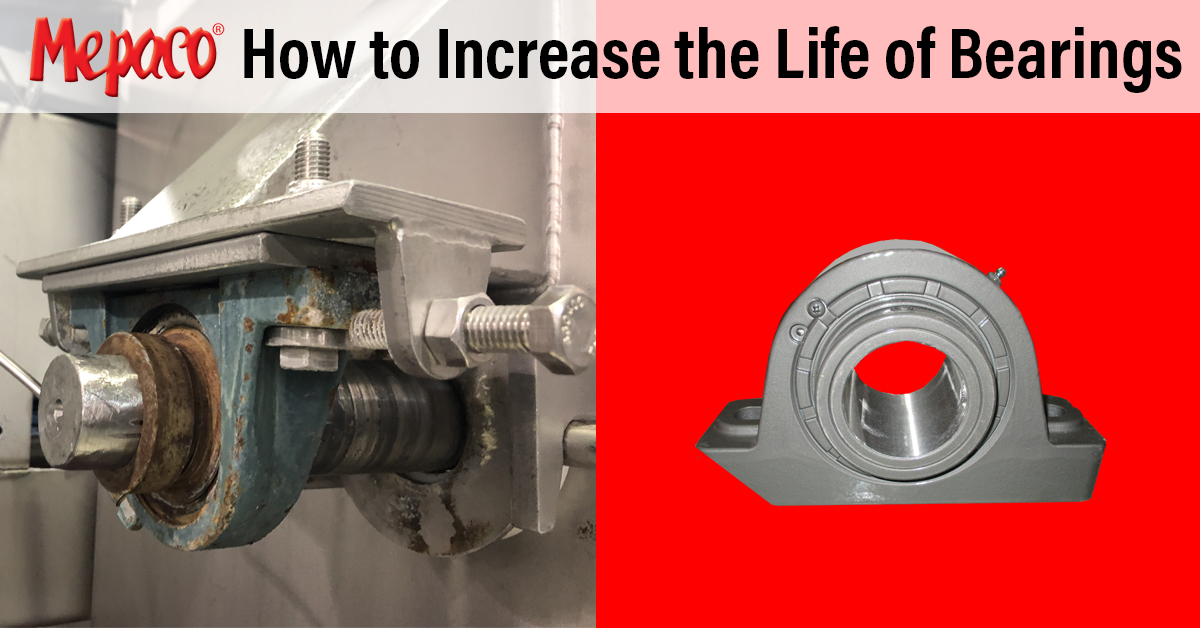

Standard bearings are steel ball bearings, mounted in a painted cast iron housing. Mepaco’s coating on standard bearings is a sealant with anti-corrosive benefits.

In aggressive applications, food processors often choose polymer bearings. The polymer bearing has a moderate up-front investment – but the total cost of ownership is lower because it requires less maintenance when used in aggressive applications.