Mepaco leverages food processing system experience to provide solutions that best meet the demands of the application for optimal performance. Versatile screw conveyors solve many bulk food handling objectives from reduced sanitation costs to enabling 24/7 continuous operation.

Articulating / Pivoting Screw Conveyors

Screw Conveyors can be designed with pivoting capabilities with casters or track systems for versatile production feeding possibilities. Another variation, the Articulating Screw Conveyor allows lowering for safe and efficient sanitation and maintenance, as well as pivoting versatility. A main consideration for an articulating or pivoting screw conveyor specified for a processing system is the need for operational flexibility.

Incline Screw Conveyor

A stationary incline screw conveyor is commonly used in smaller systems. This design is also highly adaptable, including incline, infeed, and discharge heights, and can be customized for temperature control and ease of sanitation.

Surge Metering Screw Conveyor

In large systems, Mepaco has seen a steady increase in surge metering screw conveyors due to the highly automated and scale capabilities sought by large processors. Often specified on batch processing lines, metering screw conveyors provide surge delivery to downstream equipment. Load cells are integrated into the surge screw conveyor to use the loss-in-weight method for measuring product displacement. Systems with surge metering screw conveyors reduce labor and eliminate downtime with continuous batch production.

Horizontal Screw Conveyor

Horizontal screw conveyors also offer options that solve operational efficiency to transport bulk food between equipment and processes. The standard trough design transports many types of processed foods, while the trough design can also be modified to handle large chunks of meat.

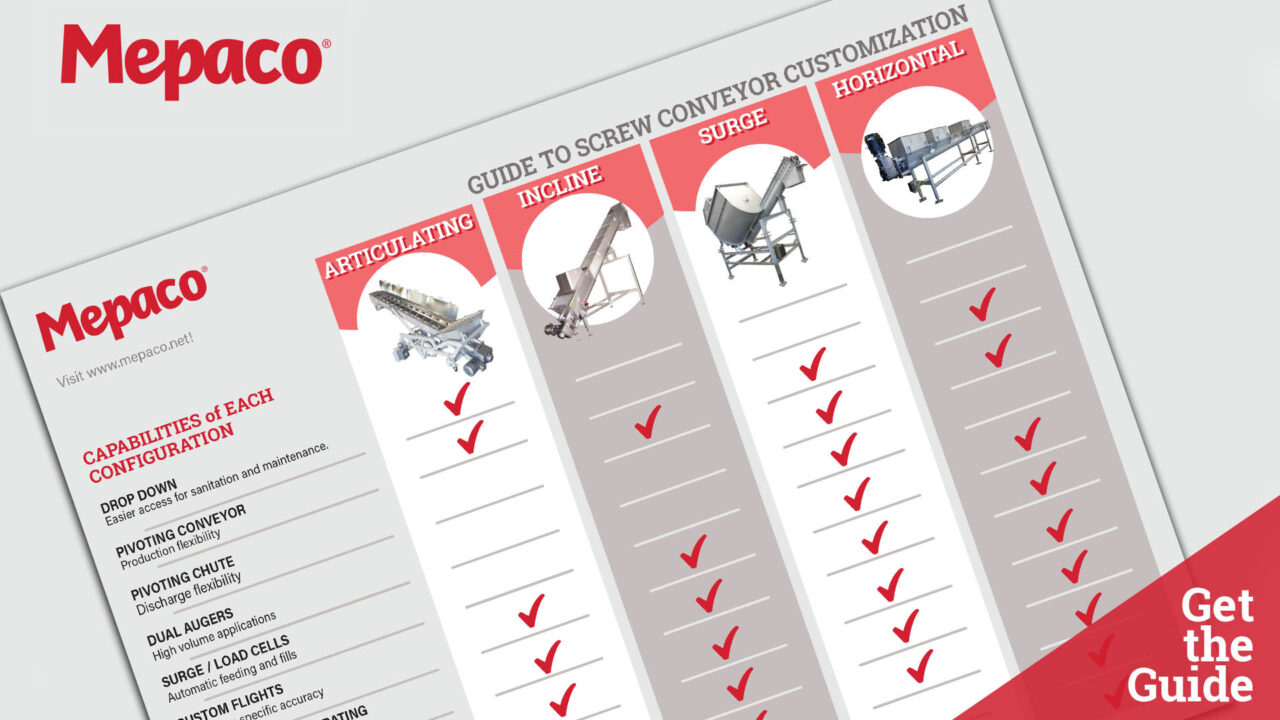

In the chart download, note the capabilities of each screw conveyor configuration, including:

Drop-down hydraulics

Pivoting

Mobile Designs

Custom Flights

Dual Augers

Load Cells / Surge

Safety Grating

Electropolished Food Contact Surfaces

CIP (Clean-in-Place) assist

Jacketing

CO2

Thermal Screws

Mepaco’s screw conveyors are customized according to the food handling and operational goals of the systems. Contact Mepaco sales engineers to learn more about highly effective and efficient food handling systems.