Mepaco’s food processing equipment solutions are engineered for the application, and with application challenges comes budget, compliance, and operational considerations. When it comes to specifying food contact surfaces, some processors require a spec to be followed and some processors are looking to fulfill sanitation and food safety goals, which might result in redefining a specification.

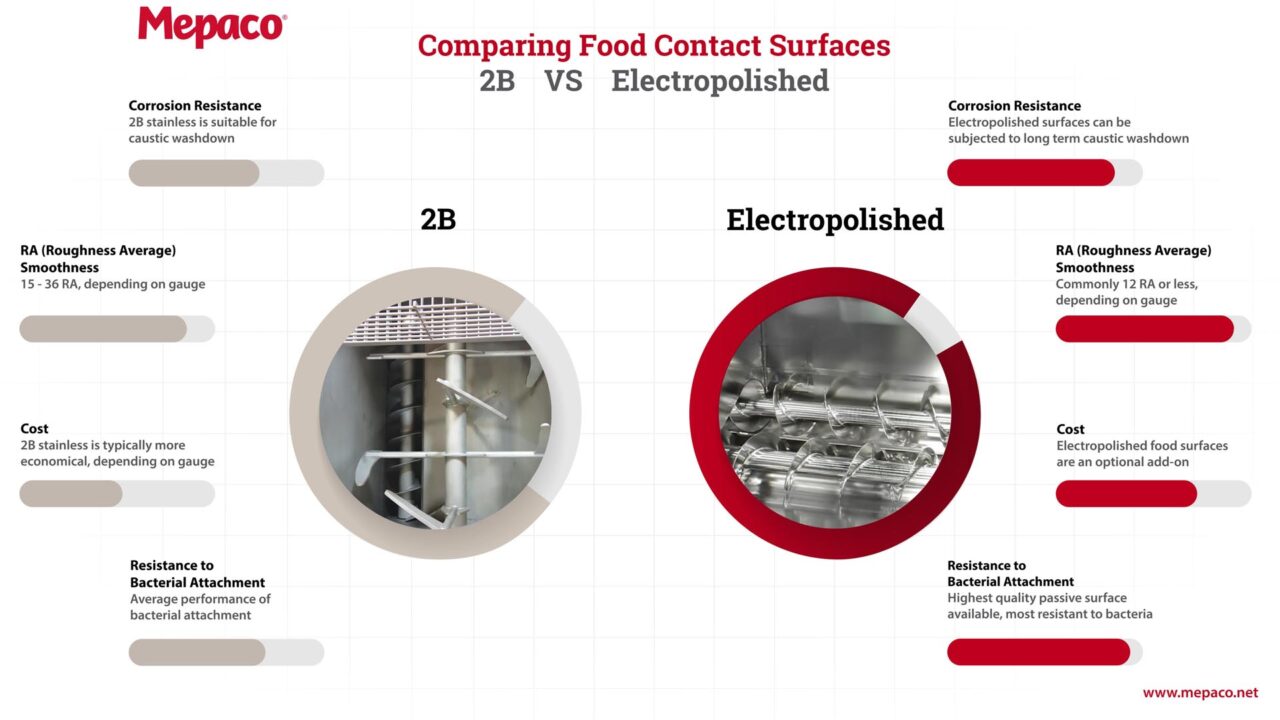

One discussion is the performance of passivated 2B stainless food contact surfaces compared to a stainless material with an optional electropolished food contact surface.

The 2B mill finish is a standard finish for 201, 301, 304, 304L and 316L stainless steel. A very low carbon, austenitic chromium-nickel steel, the 304 – 2B steel has good corrosion resistance. The 316-2B is also an austenitic chrome nickel steel with additional corrosion resistance. The cold rolling process creates a reflective finish that can be further processed. In short, 2B material is economical and is a common corrosion and heat-resistant, smooth material that is suitable for caustic sanitary washdown and meets USDA standards in many industries.

By using an electrochemical process, electropolishing smooths stainless surfaces by removing the raised areas. The measurement that rates smoothness is called Roughness Average (RA). It depends on the material, but in some cases, in-house tests have proved up to 50% increase in RA smoothness from original material, after electropolishing.

In planning food contact surfaces, it begs the question: Why should you invest in an added cost to electropolish food contact surfaces when the 2B mill finish is meeting expectations and plant standard? The answer is in the detail of the food processing application.

Processors know how their food product performs in equipment and how easily equipment performs in sanitation protocols. The 2B material, especially the 16 gauge, can have an approximate 15 RA, which is beneficial in many applications.

The electropolished finishes can have RA readings in the single digits depending on the pre-treated material. How does smooth RA translate to the performance of an electropolished food contact surface?

The National Institute of Health and the US Dept. of Agriculture have studied bacterial growth on finishes and noted that electropolishing is the most resistant surface to bacterial attachment. Apache and Mepaco have conducted in-house tests on how meat attaches to various surface finishes, finding that electropolished surfaces release food product quicker than other surfaces.

Ultimately, the decision to go with electropolished food contact surfaces comes down to these factors.

• Food Product attachment

• Resistance to bacterial attachment

• Sanitation efficiencies

• Water and chemical usage

Electropolished surfaces prove less food product and bacterial attachment which can increase cleaning efficiencies and food safety. The adoption of electropolished food contact surfaces can help processors to redefine sanitation processes to save water and/or chemicals.

Download our food safety guide “Comparing Stainless Finishes” or for a quick read, download the infographic “Comparing 2B and Electropolishing”.