With rising energy and labor costs, there is a continuous need to improve operational efficiency, cut expenses, and increase uptimes. One area of improvement is to increase the life and sanitation performance of motors, gear motors and bearings.

In consideration of the TCO (Total Cost of Ownership), some processors choose food safe stainless motors. Stainless components are very effective in harsh sanitation environments – encapsulated stainless steel food safety motors, however, are twice the cost of a standard motor.

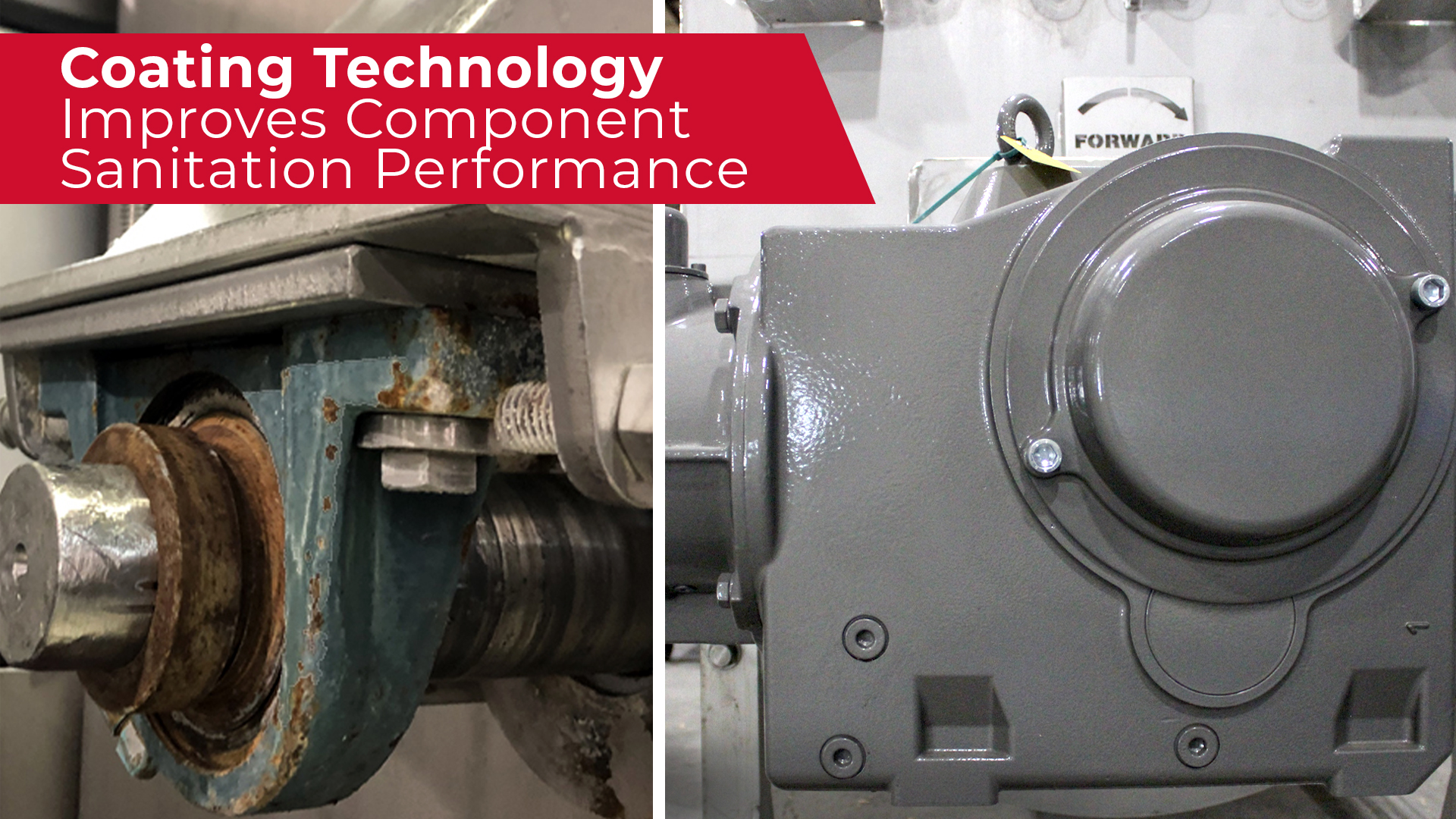

The use of painted components are common in food processing plants. Sanitation is tough on equipment with caustic chemicals spraying at 1000 psi. Once the components chip, there is a risk for the paint chips to enter the food stream – corrosion then sets in and reduces the life of the painted component.

Depending on the application, it’s best to start with food grade components. Apply the Steel-It brand coating technology – a cost effective and high-performance solution to component durability – using a special application process. Mepaco has been supplying this coating technology for years. Customers have been very satisfied with the result and continue to specify the food grade coating on components for all new projects.

The specialty coating is USDA approved. It blocks corrosion, wear, and abrasion and lasts 5+ years in harsh environments. It is formulated with 316 stainless micro-flakes, making it durable for sanitation and can be subjected to detergents, food acids, alkali, and various chemical agents.

Contact a sales manager for more information about cost saving sanitation.