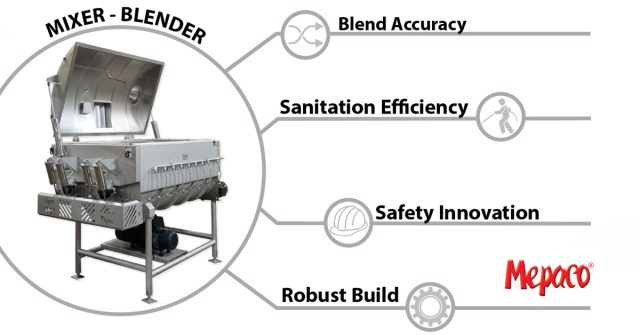

The main reasons that Mepaco Mixers have a legacy in Meat Processing is the Total Cost of Ownership, created by blend accuracy, sanitation efficiencies and proven safety features.

The overlapping paddle blender will guarantee a homogeneous blend that reaches ½% deviation in less than 90 seconds of blending, resulting in:

- More blender turns, which increase overall production rate

- Reduced breakdown of fat cells that can lead to smearing issues on equipment surfaces and fatting out of the product in downstream processes

- Yield improvements

Mixers are designed to fully discharge contents of each batch which allows for traceability from batch to batch. Electropolished finishes on food contact surfaces creates an ultra-smooth finish that produces efficiencies in sanitation.

Equipment designs, safety grates and safety relays prevent staff from reaching into equipment.

The robust build and workmanship quality, combined with blend accuracy, safety and sanitation performance is why these Mixers are still in operation after 49 years.