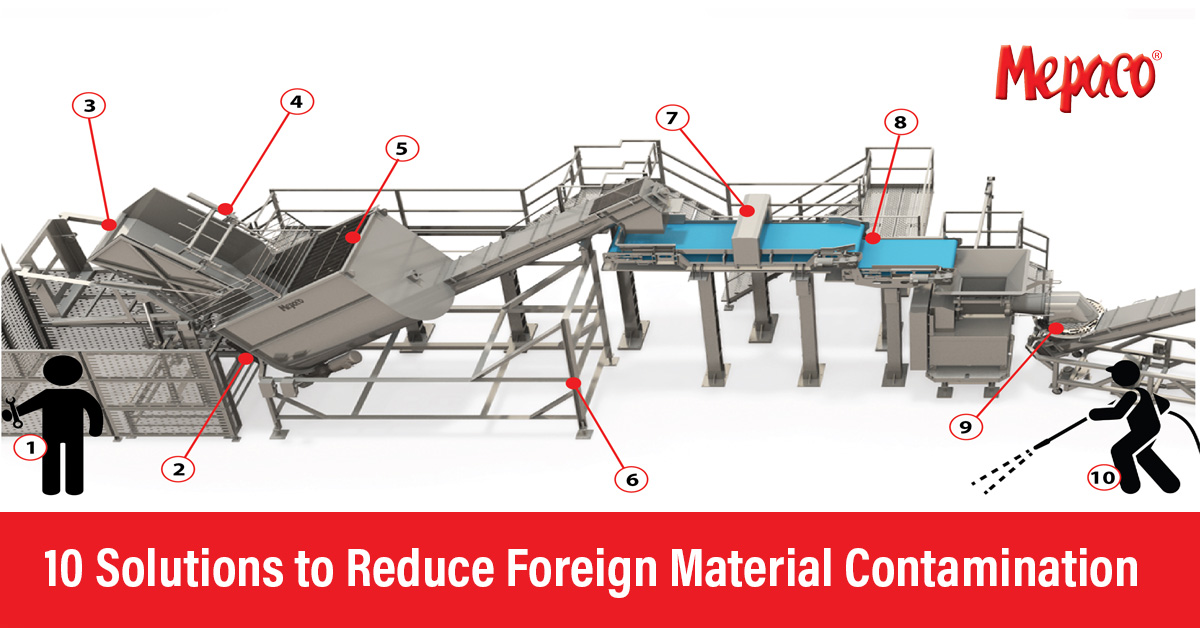

Every food processor has their own unique food safety challenges. Here is one process room scenario where attention to process layout, equipment modifications and training can significantly reduce foreign material contamination.

- Operator Training High-volume automation brings a high degree of risk for machinery fatigue and vibration. Over time, nuts and bolts will

loosen and moving components that become misaligned can produce loose metal. In addition, the equipment operator must completely understand how every facet of the equipment works, including the symptoms when it isn’t running properly. - Seal Maintenance Many causes of downstream food contamination are the result of a broken seal, improper packing or a grooved or broken shaft. COP

(clean-out-of-place) split seals should be checked for wear and sanitized daily. Seals should be part of the preventative maintenance program and included in your parts inventory. - Pallet Retention System (PRS) The PRS is integrated into the loading base of select pallet dumper equipment. It is engineered to securely remove the pallet away from the dump zone so that wood, nails, and other impurities are prevented from entering the product stream.

- Liner Hold Down Another option on pallet dumper equipment is the liner hold-down mechanism which is engineered to hold back the liner during the dumping process. The liner hold-down prevents the plastic from entering the food zone and prevents the operators from having to lean or reach over the food zone to control the liner.

- Electropolished Food Contact Finishes Processors often choose electropolished food contact surfaces on equipment which provide the smoothest surfaces for ease of sanitation, and provide the highest level of corrosion resistance, including the performance of weldments.

- Open-frame Construction Open-design framework with butt weld type, ground to a smooth finish provides superior sanitation performance. Bolt and thread designs should be hygienically designed with enclosed threads.

- Metal Detection In this example, the metal detector is placed near the beginning of the grind-blend line to detect and circumvent tramp metal

from entering the grinder and downstream equipment. - Drop-Conveyor Inspection The drop belt conveyor shown in the layout allows trim meat to be flipped during conveyance and allows for visual

inspection of foreign material before the product is transported downstream. - Grinder Maintenance Foreign material can include metal shavings and shards from grinders. Keep the grinder finely tuned and in proper

alignment; keep the pins, bushings, heads and knives in well maintained condition. - Sanitation Training Confirm that the sanitation crew completely understands the proper disassembly and reassembly of all COP (clean-out-of-place) components. Improper installation may create wear points on machinery which can lead to contamination.